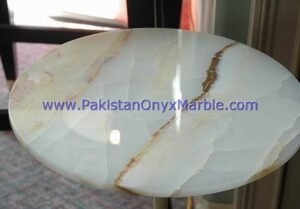

Light Green Onyx Table Tops Design

Onyx Table Tops Design: Shapes, Sizes, and Manufacturing Process

Onyx table tops with their captivating designs are a testament to the fusion of natural beauty and artistic craftsmanship. Let’s delve into the various shapes, sizes, and the detailed manufacturing process involved in creating these exquisite table tops.

Shapes and Sizes: Onyx table tops come in a range of shapes and sizes, each contributing to the overall aesthetic and functionality:

1. Rectangle Onyx Table Tops: Rectangle tops exude classic elegance and offer ample surface area. Common rectangular sizes range from small coffee table dimensions of 36 inches by 24 inches to larger dining table dimensions of 72 inches by 40 inches.

2. Round Onyx Table Tops: Round tops foster a sense of unity and provide cozy gathering spaces. Round table diameters vary, starting from around 24 inches for coffee tables to 60 inches or more for larger dining tables.

3. Oval Onyx Table Tops: Oval tops combine the grace of round tables with the functionality of rectangles. Sizes often range from 48 inches by 30 inches for coffee tables to 96 inches by 48 inches for grand dining tables.

4. Square Onyx Table Tops: Square tops exude modern symmetry and can be versatile in various settings. Square table dimensions range from 24 inches by 24 inches for small side tables to 48 inches by 48 inches for dining tables.

Manufacturing Process: Crafting onyx table tops is a labor-intensive process that involves both technical expertise and artistic vision:

1. Material Selection and Preparation: High-quality onyx blocks are carefully selected based on their unique color and pattern. The onyx is then cut into manageable slabs of appropriate thickness.

2. Design and Planning: The table top’s design is conceptualized, incorporating the chosen shape and the desired inlay or veining patterns. The planning phase ensures a harmonious composition.

3. Cutting and Shaping: The onyx slabs are cut into the specific shape of the table top using diamond-tipped saws. Intricate curves and edges are shaped with precision to achieve the desired form.

4. Inlay and Veining (Optional): Inlay techniques involve inserting contrasting stones or metals into the onyx to create intricate patterns or designs. Natural veining present in the onyx can also be highlighted to enhance its visual appeal.

5. Polishing and Finishing: The onyx surface is meticulously polished to reveal its inherent luster and beauty. Special attention is given to achieving a smooth and reflective finish.

6. Quality Control: Each table top undergoes stringent quality checks to ensure that it meets the highest standards in terms of craftsmanship, shape accuracy, and surface quality.

7. Edging and Mounting: Edges are carefully smoothed and, if desired, decorative edge profiles are created. Table tops are then mounted onto suitable bases or frames, whether metal, wood, or other materials.

8. Final Presentation: The completed onyx table top stands as a stunning work of art, marrying the natural allure of onyx with meticulous craftsmanship. It’s ready to grace homes, offices, or any space seeking an extraordinary blend of aesthetics and function.

Our Advantages

Natural and Safe: We use natural and safe marble mined from high-quality sources to ensure the quality of our products.

Technology: Our skilled workers employ safe and advanced equipment to produce the best-quality slabs.

Variety of Types: We offer a wide range of textures to meet your construction needs, providing you with various options to choose from.

Packaging: We use professional wooden cases for shipping and implement safe inner protection measures to avoid any damage during transportation.

Supply Ability: We can provide up to 1000 square meters of slabs etc.

Port: Our products are shipped from Karachi, Pakistan.

Our Services for You:

1. We offer competitive prices, along with warm and friendly customer service, while ensuring high-quality products.

2. We can accommodate your reasonable design requests and make changes to our original designs to meet your needs.

3. We welcome custom orders for different sizes or OEM designs tailored to your preferences.

4. Before shipping, we will take detailed pictures for you to check the quality and ensure it meets your expectations.

5. We are flexible and accept orders of less than a full container load.

6. In general, we strive to deliver your order within 30 to 45 days, ensuring prompt and timely service.

7. With over 17 years of experience in exporting, we have the expertise to make your order process smooth and efficient.