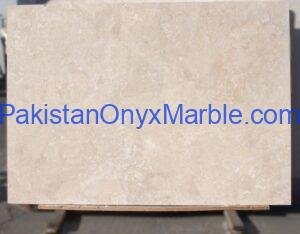

Travertine Slabs Beige Color Cross Cut

Beige Color & Cross-Cut Character

Beige Color: Ranges from light cream and ivory to warmer golden or nutty beiges. It provides a neutral, elegant, and timeless backdrop that complements a wide range of design styles, from traditional to modern.

Cross-Cut (Cross-Grain): This refers to how the stone block is sliced. Instead of cutting with the sedimentary layers (vein-cut, which shows long linear patterns), it is cut across the layers.

Resulting Appearance: This reveals the characteristic hollows and cavities of travertine as rounded, organic pores and a more chaotic, “busy” pattern of swirls and clouds. It highlights the stone’s natural formation and texture, giving it a more rustic, earthy feel compared to the linear elegance of vein-cut.

Common Sizes

Travertine slabs are available in dimensions similar to other natural stones. Beige cross-cut is widely stocked.

Standard Slab Sizes:

Length: Typically between 96″ to 120″ (8 to 10 feet).

Width: Commonly 48″ to 72″ (4 to 6 feet). 60″x120″ is a very popular modern size.

Thickness: For countertops, the standard is 2 cm (¾”) or 3 cm (1 ¼”). 3 cm is more robust for kitchens without needing a plywood substrate. For shower walls and other cladding, 1 cm (⅜”) thick slabs are also common.

Tile Sizes (if cut from slabs): Many of the slab finishes can also be applied to tiles. Common tile sizes cut from this material include 12″x24″, 24″x24″, 18″x36″, and large-format 24″x48″ or 36″x36″.

Popular Finishes for Beige Cross-Cut Travertine

The finish dramatically changes the stone’s look, feel, and performance.

Honed & Filled: The most popular finish for interiors.

Process: The surface is ground to a smooth, matte, non-reflective finish. The natural pores are filled with a matching resin or cement.

Look: Soft, velvety, contemporary. It evens out the color and provides a uniform surface.

Use: Ideal for flooring (less slippery than polished), countertops, shower walls, and interior cladding.

Polished:

Process: The stone is buffed to a high-gloss, reflective shine. Pores are usually filled.

Look: Elegant, formal, and deepens the color. The beige tones become richer. The cross-cut pattern becomes very vivid.

Use: Feature walls, bathroom vanities, interior flooring in low-traffic areas, and furniture tops. Can be slippery when wet.

Brushed / Tumbled:

Process: The stone is mechanically brushed or tumbled to wear down the edges and surface, creating an aged, textured, slightly rough feel. Pores remain open.

Look: Rustic, old-world, weathered. Enhances the stone’s natural texture and provides excellent slip resistance.

Use: Perfect for pool decks, patios, garden paths, and rustic-style interior floors.

Chiseled / Antiqued:

Process: The edges are hand-chiseled to create a rough, irregular perimeter. Often paired with a brushed or honed surface.

Look: Artisanal, old-world charm.

Use: Primarily for wall cladding, fireplace surrounds, and decorative borders to create a Mediterranean or rustic aesthetic.

Natural / Unfilled (Less Common for Slabs):

Process: The stone is cut and honed but the pores are left open.

Look: Very textured, natural, and porous. Requires more maintenance.

Use: Mostly for exterior applications where drainage or extreme slip resistance is needed, or for specific rustic interior features.

Primary Uses

Interior Uses:

Flooring: A top choice for whole-house flooring, especially in honed finish. It is durable and beautiful. Note: It is softer than granite and can etch from acids (lemon juice, vinegar), so sealing is crucial.

Bathrooms: Excellent for shower walls, shower floors (in smaller tiles), vanities, and tub decks. The honed finish is preferred for wet areas for slip resistance.

Kitchens: Used for countertops (honed is popular, but will show wear) and backsplashes. Be mindful of etching from acids.

Feature Walls: Creates a stunning, natural accent wall in living rooms or entries.

Fireplace Surrounds: Adds warmth and texture.

Exterior Uses:

Pool Decks & Coping: The brushed/tumbled finish is the #1 choice for pool decks due to its superior slip resistance and cool surface. Cross-cut’s texture is ideal for this.

Patios & Walkways: Provides a beautiful, durable surface that ages gracefully.

Exterior Cladding: For Mediterranean or rustic-style home exteriors.

Important Considerations & Maintenance

Sealing is Mandatory: Travertine is a porous calcium carbonate stone. It must be sealed with a high-quality penetrating sealer upon installation and re-sealed periodically (every 1-3 years depending on use) to resist staining, water absorption, and etching.

Etching: Vulnerable to acids (citrus, wine, vinegar, many cleaners). An etched spot will appear as a dull mark on a polished finish or a light spot on a honed finish. Using a honed finish helps camouflage this.

Durability: Softer than granite or quartzite. It can scratch and chip more easily, but this can add to its “lived-in” patina over time.

Variability: Natural stone has color and pattern variation from slab to slab. It’s essential to view and select your actual slabs (slab lot) for a project.

Our Advantages

Product Name

Beige Travertine Slabs – Vein Cut

Origin

Pakistan

Stone Type

Natural Travertine (Vein-Cut)

Color

Beige / Light Beige with linear horizontal veins

Cut Type

Vein-Cut (parallel to bedding layers for linear pattern)

Standard Slab Sizes

Thickness:

2 cm (20 mm)

3 cm (30 mm)

Custom: 4–6 cm (on request)

Length: 240 – 300 cm

Width: 140 – 185 cm

Approx. Weight

2 cm: 45–55 kg/m²

3 cm: 70–80 kg/m²

Available Finishes

Honed (most demanded)

Polished

Filled Honed

Filled Polished

Unfilled Honed

Brushed

Sandblasted / Bush-hammered (exterior use)

Surface Treatment

Resin filling or cement filling (optional)

Factory calibrated thickness

Edge trimming on request

Applications / Uses

Interior flooring

Wall cladding & feature walls

TV / media walls

Bathrooms & showers

Kitchen backsplashes & countertops

Stair treads & risers

Exterior façades (sealed finish recommended)

Hotels, restaurants, spas

Offices & commercial buildings

Furniture tops & décor manufacturing

Packing Details

Seaworthy wooden bundles

Plastic sheet + foam/rubber separation

Edge protection for long-distance shipping

Container Loading (Approx.)

20 ft container:

2 cm slabs: 350–450 m²

3 cm slabs: 220–280 m²

(Depends on slab size mix)

Shipping Terms

FOB Karachi Port

CNF / CIF on request

Payment Terms

30% advance, 70% before shipment

LC at sight (for large orders)

MOQ

100–150 m² per finish / thickness

HS Code

680291 (Travertine / Limestone slabs)